Leverage next-gen technology to get the visibility (and security) you need

When you walk into the office, you expect the lights to come on and the computers to whirr to life. At home, you might want to start the day with a hot cup of coffee and close it out with a warm, soaking tub.

None of that is possible if utilities and municipal services aren’t running efficiently to keep power and water running. Critical operations rely on uninterrupted utility services; in health care, for example, that could mean life-or-death scenarios. And today, there’s a growing risk of not having reliable water, gas and electricity delivery, not to mention the potential of a major system breakdown on the line.

For decades, operators have deployed and relied on wireless radio systems as the backbone for critical infrastructure in utilities and municipal services. From monitoring water levels to controlling energy distribution, these systems provide essential connectivity between field devices and supervisory control and data acquisition (SCADA) systems. In basic terms, these systems let operators keep track of what’s happening across that service and at key touchpoints.

However, many of these radio networks were installed some 20 or 30 years ago, leaving them on shaky ground for continued health and functionality, resulting in significant risks today that their outdated technology simply will fail. If a system component breaks, limited replacement parts make repairs tricky. On top of that, regulatory requirements for maintaining and reporting on these systems are rapidly increasing.

Fortunately, utilities and municipal services can now embrace migration to contemporary radio platforms through easier and less disruptive approaches to meet growing demands for digital infrastructure, cybersecurity and operational reliability. Careful upfront planning can streamline the migration and minimize a host of risks that come with a complex and distributed radio network.

Why legacy radios can’t keep up

For many organizations, the wireless radio systems in use today — whether in water-treatment facilities or connected to pipelines running thousands of miles away — were installed decades ago. These legacy systems often rely on analog or serial-based technologies, such as RS232 and RS485. While these devices have provided reliable service, most simply have reached the end of their life cycles, with many operating on borrowed time, which puts critical services at significant risk. Replacement components are becoming increasingly difficult to source as manufacturers have phased out older chipsets, often due to supply chain disruptions and shifts in production following the COVID-19 pandemic.

In addition to obsolescence, these systems lack the capabilities required for today’s data-driven operations. Older radios were designed for basic status updates, such as whether a pump was running. Modern systems require high-speed, secure data transfer from a growing variety of field sensors, cameras and controls.

Operators today expect far more from their systems — and rightly so, given the sophistication used in other parts of their functions. They want visibility into environmental data, equipment condition, intrusion detection and real-time alerts — all capabilities that legacy systems simply cannot support.

Modern radio systems deliver substantial upgrades to legacy infrastructure, with integrated diagnostics, advanced security and seamless interoperability across industrial protocols - enabling real-time asset visibility and control to meet the evolving demands of utility operations. Source: Weidmuller

As aging infrastructure across utility, municipal and industrial sectors faces increasing regulatory pressure, smarter systems have become essential. Wireless radios play a critical role in maintaining the health and uptime of large-scale operations to help identify issues early, before minor faults escalate into major disruptions. Source: Weidmuller

Threats to compliance and public safety

Maintaining visibility and communication with remote infrastructure isn’t just an operational goal; these are not just data points for day-to-day functions. Keeping systems running underpins the ability of utilities and municipalities to maintain public health and safety, not to mention reduce environmental risks.

In many cases, operators face strict regulatory oversight and requirements to monitor what’s happening at key intervals. Failure to report system status within mandated time intervals can result in steep fines. In Virginia, for instance, the Environmental Protection Agency (EPA) can assess penalties reaching tens of thousands of dollars for each reporting period missed or for failure to comply with mandated monitoring and reporting requirements.

The consequences of outdated systems go beyond fines. Loss of visibility and control can lead to real-world disruptions, including untreated water releases, power failures and environmental hazards. In a recent real-world example, a water authority experienced a major outage due to a failed communication network, resulting in service loss and a regional boil notice for nearly a week in early January. The downstream impact was that businesses and restaurants shut down, and non-emergency medical procedures were deferred.

Beyond replacement: the opportunity in migration

How operators look at a potential migration is important: It’s not just a matter of replacing failing equipment. Migration presents an opportunity to deliver step changes that improve system resilience, security and functionality. Today’s radio systems deliver an expanding array of advanced features, including Ethernet communication, integrated diagnostics, remote management and support for multiple protocols.

Utilities can also take advantage of modern security features that weren’t available when they installed legacy systems. Today’s radios support AES 256-bit encryption, advanced IP filtering and multi-level password protection. These capabilities help safeguard critical infrastructure from cyber threats, an increasingly important priority across all sectors.

Additionally, new systems are designed for better spectral agility, enabling them to operate effectively and efficiently even in high-noise industrial environments. They also offer higher throughput, allowing more devices to be connected and more data to be transmitted in real time.

Migrating with minimal disruption

One of the most common misconceptions about wireless migration is that it must be a disruptive, all-or-nothing process. In reality, effective migration strategies are designed to be phased and minimally invasive. This allows legacy and modern systems to run in parallel while transitioning, reducing risk and enabling utilities to control both the pace and budget of the upgrade.

Modern radios, together with the base station repeater and intelligent switch, form a comprehensive wireless migration solution, enabling legacy networks to be upgraded in a phased, low-risk approach. This ensures minimal disruption and optimal system performance throughout the transition. Source: Weidmuller

A successful migration plan typically includes four key steps:

1. Site survey and planning

Before any equipment is replaced, a thorough site assessment is conducted to evaluate existing infrastructure, signal quality, terrain and tower requirements. A combination of paper surveys and on-site visits helps determine whether any physical changes — such as increasing antenna height — are needed to maintain or improve coverage.

2. Migration roadmap

With survey data in hand, a migration roadmap is created. Utilities identify the most critical sites for initial upgrades, often starting with areas experiencing failures or where reporting is most urgent. From there, migration proceeds in clusters, allowing for manageable and efficient deployment. Each cluster is tested and optimized before moving on to the next.

3. Hardware and software implementation

New radios are installed at control centers and remote sites, typically running in parallel with existing equipment during the transition. This avoids service interruptions and allows time for configuration and performance verification. Field radios are either swapped into existing enclosures or installed as part of preassembled, plug-and-play panels to minimize downtime.

SCADA systems are updated to communicate with the new hardware, and additional sensors or monitoring tools can be added at this stage to take advantage of expanded capabilities.

4. Training and ongoing support

Technician training is vital to a successful migration. Training typically takes place in stages, ensuring that different teams are prepared to work with the new system’s hardware and software. Migration partners provide hands-on guidance during setup and offer long-term support to troubleshoot issues and help utilities optimize the new technology.

This phased, collaborative approach ensures continuity of service while upgrading to a system that can meet current and future operational needs.

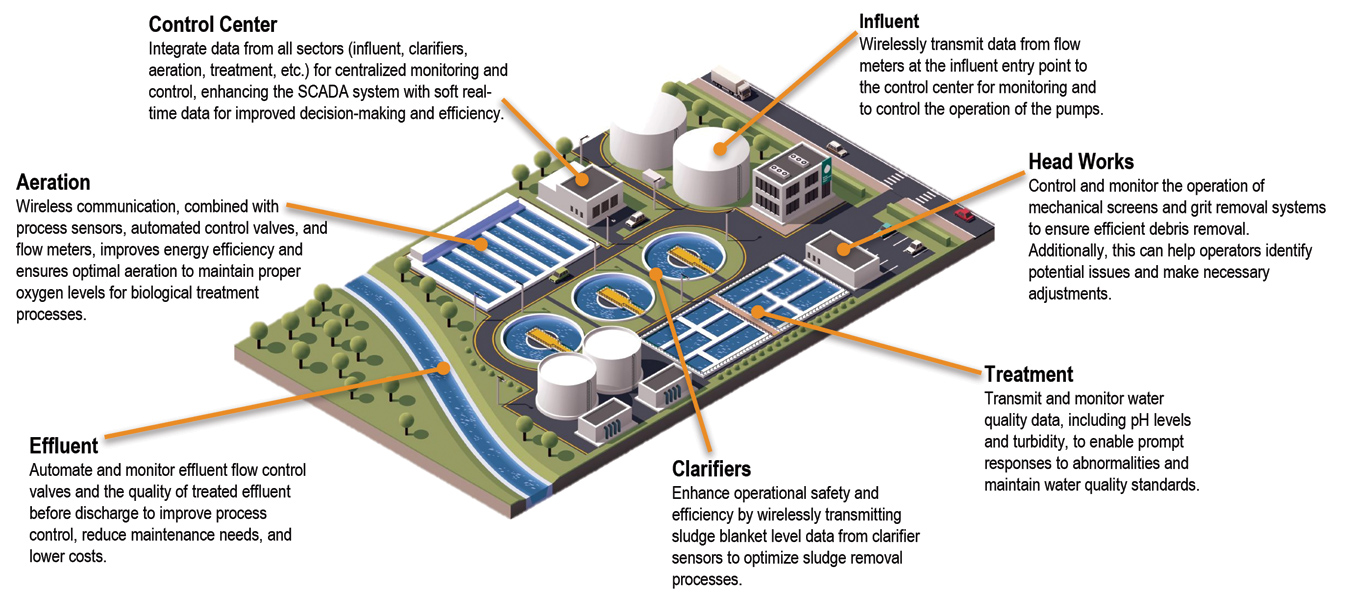

Modern wireless radio systems bring new intelligence to every stage of the water treatment process, from real-time monitoring of pH and turbidity to centralized SCADA integration. As utilities face aging infrastructure and tighter regulations, wireless migration enables smarter, more resilient operations with minimal disruption. Source: Weidmuller

What the modern system delivers

Migrating to a new wireless platform unlocks significant benefits.

Cybersecurity: Water and power lines are a core target for those intent on harming a community. Legacy radio networks have demonstrated their weaknesses to hackers, and utilities need greater visibility into who is accessing often-remote locations.

Multi-level password protection is the first step. Modern radios meet or exceed standards like ISA/IEC 62443 and align with federal mandates under the Cyber Resiliency Act, which requires compliance with new standards by 2027. Coupled with cameras, these next-generation radios protect against unauthorized access, safeguard data and ensure system integrity.

Expanded visibility: Operators can monitor variables such as flow rate, temperature, intrusion, vibration and pressure from a central control system or even a mobile device. Legacy networks faced restrictions on the number of radios that could be deployed, which limited the input of data variables. With that expanded data gathering comes faster speeds as well.

But monitoring goes beyond delivering the end services. In the case of gas pipelines, for example, accurately tracking the product’s flow is also critical to a business’s bottom line. As gas is handed off from supplier to supplier, a 1% error can be worth millions.

Redundancy and reliability: New base stations are configured with redundant radios to ensure uninterrupted communication. Advanced systems also support plug-and-play installation to minimize service outages. Plus, since many radio networks were installed a quarter of a century ago or more, staff members and technicians with experience in how they work and their history have likely long left the organization, leaving a significant knowledge gap.

Data-driven decision making: Enhanced connectivity allows organizations to deploy AI-based tools for predictive maintenance, optimize system performance and respond to issues before they escalate. These new radio networks integrate seamlessly with the organization’s SCADA platform, making it easy to access greater information at a few keystrokes.

Consider a water pump, where the basic question has long been “Is it running or not?” Now, these radios can answer increasingly more granular questions that drive specific action: Has someone come in to change the program? What is the optimal time for the pump to be on? Are there any blockages? Are there any potential overflows?

Future-Proof Design: Dual protocol support (serial and Ethernet) ensures compatibility with both legacy and modern SCADA and PLC systems. Modular hardware allows easy expansion and supports integration with edge platforms and cloud analytics. Modern wireless radios are built for scalability and expansion, with plug-and-play functionality.

When emergencies strike

While a full migration typically takes 6 to 12 months, emergency upgrades can be completed far more rapidly. In situations where legacy radios have already failed, utilities can install new radios and restore SCADA communication in as little as one day — provided power is available and no programming changes are needed.

These rapid deployments serve as a critical stopgap, stabilizing operations while a long-term migration plan is developed. Having this capability in reserve provides reassurance that service disruptions can be addressed quickly and safely.

Building a smarter infrastructure

SCADA systems have evolved significantly over the past three decades. Once built on command-line interfaces and limited by data bandwidth, today’s systems are fully graphical and increasingly AI-enabled. They provide operators with a comprehensive view of infrastructure health and allow automated control actions based on real-time data.

With more data available from upgraded field devices, utilities can now shift from reactive maintenance to predictive operations. This increases uptime, extends the life of assets and enables more strategic capital planning.

A trusted partner in migration

The success of any migration depends on the strength of the planning, the quality of the hardware and the depth of support. A complete solution includes not just radios, but also routers, switches, network configuration and SCADA integration.

One Richmond, Virginia-based provider of smart industrial connectivity and automation solutions approaches migration opportunities as a solution partner, not just a supplier. The company offers systems that are modular, scalable and secure, with the flexibility to fit the unique needs of each customer. Whether through wired, wireless or cellular options, the Richmond-based company provides the architecture that supports secure, uninterrupted communication.

More specifically, this provider's wireless radio system migration solution is comprised of Ethernet/serial modems and I/O radios — or a combination of both — along with Intelligent Switch (IAS) and Base Station Repeater (BSR). The IAS, a fully redundant RF antenna switch, pairs with the BSF to deliver a robust, reliable and redundant hot standby solution for base or repeater sites. Additional pre-configured systems streamline migration.

Most utilities cannot shut down their networks for extended periods. That’s why this solution supports running legacy and new systems simultaneously, which reduces downtime. This makes migration more accessible and allows teams to modernize infrastructure without jeopardizing operations.

A call to action

The time to modernize is now. Regulatory pressure is mounting, the risk of failure is rising, and the opportunity for improved performance has never been greater.

Migration isn’t just about replacing what’s broken: It’s about preparing for the future.

With the right strategy, partners and tools, utilities and municipal services providers can turn a daunting challenge into a transformative opportunity. Whether needing to eliminate legacy bottlenecks, protect against cyber threats or gain deeper operational insight, a modern wireless infrastructure is the foundation for smarter, safer service delivery.

Today’s technology offers a streamlined strategy for gaining that critical peace of mind that operators can keep the water treatment continuing, oil and gas pipelines flowing, and the lights turned on for every customer.

Andrew Barco is global program senior director for Industrial Ethernet at Weidmüller, where he leads strategic initiatives in automation, connectivity, industrial networking and cybersecurity. He holds degrees in electrical and electronics engineering and a Master’s in business leadership & marketing. Barco serves on IEEE and ISA technical advisory committees, shaping networking and cybersecurity standards in industrial automation.

Nicole Riggle has more than 26 years of experience with Weidmuller. She focuses on automation solutions that support critical infrastructure and a wide range of industry applications. Riggle holds an Associate of Applied Science degree in computer electronics technology with a major in microelectronics technology from ECPI University. Riggle has received certifications in Industrial Electronics Technology and automation software platforms from accredited training programs.