Semiconductors moved to the center of the energy transition about 10 years ago — a shift rivaled only by the invention of the alternator nearly 200 years before that. And while the alternator made AC power the dominant technology, today it’s DC sources that dominate energy generation, storage and consumption in solar panels, batteries and data center processors.

The next 10 years will be about interconnecting more sources and consumers of energy by making the high-voltage AC transmission grid smarter. Although semiconductors have played a significant role in driving down the cost of clean energy, breakthroughs will be necessary as areas with the best opportunities for solar and the cheapest grid connections start to reach saturation. From a semiconductor perspective, the technologies already exist for the large-scale adoption of clean energy. Making AC-to-DC conversion more efficient improves the return on investment (ROI) in solar inverters, while also improving charge and balance energy stored in batteries to drive higher penetration in mature solar markets. Doing so will improve the monitoring of energy supply and demand, and enable new technical and commercial arrangements to better balance the grid.

Making it easier to integrate solar energy with the existing grid

According to the International Energy Agency (IEA), solar energy is the fastest-growing source of energy in the world, growing 35% year-over-year in 2024. By 2030, solar will be the largest source of energy globally. This means that solar inverters are employing the grid-forming strategy as high-voltage semiconductor-based power converters replace electromechanical alternators in coal- and natural gas-fired power plants.

Texas Instruments (TI) has a long history of partnering with the solar energy market, as our analog and embedded portfolio make this transition affordable and easier to integrate with the existing high-voltage grid. New power topologies based on our microcontrollers (MCUs), gallium nitride (GaN) field-effect transistors (FETs), gate drivers and power supplies help improve efficiency in the conversion between AC and DC power and shrink the size of passive components like inductors, capacitors and heat sinks, which make up most of the size and cost.

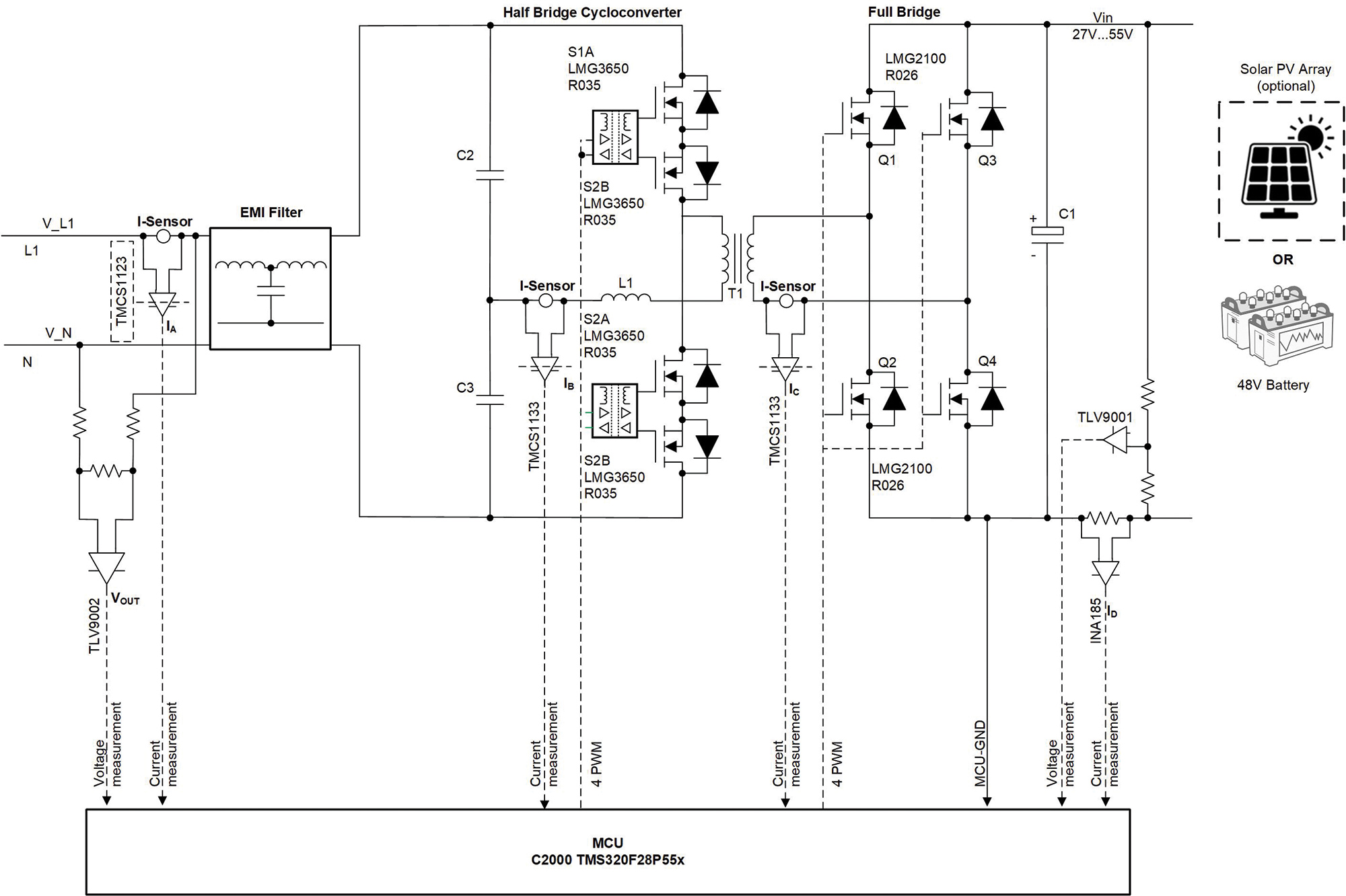

Figure 1: 600W GaN-based single-phase cycloconverter reference design schematic. Source: Texas Instruments

Efficiency improvements make solar more cost-competitive by converting more energy with fewer losses, which then enables smaller heat sinks and cooling fans. As shown in Figure 1, single-stage topologies, as shown in the 600W GaN-based single-phase cycloconverter reference design, reduce the need for some passive components and, with higher switching frequencies, make other components smaller. The precise control offered by our combined MCU, gate drivers and FETs helps designers implement a cycloconverter while keeping electromagnetic interference low.

Historically, solar inverters using the grid-following strategy output a waveform that follows the frequency set by synchronous generators on the grid. Inverters employing this strategy have fast-frequency response capabilities that define the waveform and can respond to changes in frequency by injecting additional power from solar inverters or batteries. South Australia is the first energy market in the world to test this at a large scale, and the TI C2000 real-time MCUs runs fast current and voltage loops that adjust current and voltage in real time.

Current and voltage sensing aided by edge AI

Measuring current and voltage has always been fundamental to an energy system. In a system with both AC and DC power, measurement takes new forms such as arc detection, residual current detection and insulation monitoring. These types of measurements require system solutions where everything from the sensor to the signal chain and processing will determine the uptime of end equipment, and thus its reliability and cost of ownership. TI helps accelerate the adoption of technologies such as edge artificial intelligence (AI) and new sensor types to help improve system performance and drive down costs.

It’s important to closely collaborate with the solar industry to drive standards designed to improve safety, as well as the quality of service that the equipment is delivering. Arc detection, which is a primary safety function in any solar inverter, is an example where a combination of analog and embedded processing devices helps improve systems over time. Our analog signal-chain devices enable customers to build the best analog filter, from current sensors to analog-to-digital converters. Breakthroughs in process technologies have also improved accuracy over time. Increased processing power and the addition of AI accelerators reduce false trips and adapt readily to new environments, making management easier without manual reconfiguration.

Energy storage enables solar 24/7

As solar energy becomes more abundant and costs drop, users want to be able to access it constantly. This is where energy storage through batteries has become an unsung hero. There are energy markets where batteries are the single largest source of energy at certain times of day. Batteries comprise thousands of individual battery cells that all need monitoring in real time, as they will charge and discharge several times a day in order to better align energy supply and demand. Batteries also stabilize the grid during normal operation, as they can sink or source power within milliseconds to help compensate for short-term and local variations in supply and demand.

Electrochemical impedance spectroscopy (EIS) is an example of a technology being developed in a collaboration between semiconductor manufacturers, system integrators and battery cell vendors. The benefits of EIS include better state-of-charge and state-of-health calculations and improved battery safety. EIS, combined with pack and cell balancing, demonstrated in TI’s serial resonant converter dual bridge (SRC DB) for energy storage systems (ESS) pack balancing reference design and active battery cell balancer reference design helps improve power density in ESSs and increases battery cell lifetimes, further improving ROI for ESS installations.

Data centers are driving growth in power demand

The primary drivers of increased energy demand in the coming years will be the electrification of transportation and manufacturing and data centers. According to the Electric Power Research Institute (EPRI) study, data centers are expected to consume 8.4% of all power in the U.S. by 2030, up from about 4.5% in 2024. Semiconductors improve data from a remote node in the grid, such as an electric vehicle (EV) charger, a robot-equipped factory or a server in a data center. Each node — if connected and aware of network information such as future demand, prices and local storage capabilities — can help better align supply and demand and lead to lower costs for everyone.

Edge processing with low power, the ability to run applications, high security, wired and wireless connectivity options and TI’s commitment to contribute to and support standards such as Wireless Smart Utility Network (Wi-SUN) and ISO15118 help designers integrate both hardware and software. Edge AI enables an MCU or microprocessor in an edge node-like circuit breaker or electricity meter to run a trained model with the help of onboard accelerators at very low cost and power. This capability helps enable load disaggregation so that users can make smarter decisions about when to charge an EV or make data center calculations to better align supply and demand.

Conclusion

It should not come as a surprise that the energy transition is starting to feel difficult. The progress made in the last couple of years includes conquering the easiest challenges. It’s now time to apply high-voltage power conversion, current sensing, battery management and edge processing at a large scale. This phase will require making the conversion between AC and DC more efficient and affordable, and improving the ROI on batteries to enable more solar in mature markets and support peaks in developing markets. Edge AI has the potential to better align supply and demand, eliminate false trips in safety systems and improve the user experience.

Henrik Mannesson is the general manager for Energy Infrastructure at Texas Instruments. He works alongside his team to help customers solve design challenges in smart meters, solar energy, EV charging and grid automation with the goal of making the grid greener, smarter and more resilient.